|

Sol-Gel Materials and Nanotechnology Center

of Excellence

Address: ul. Smoluchowskiego 25

50-370 Wrocław, Poland

phone: (+48 71) 320 21 18

fax: (+48 71) 321 12 35

Email: sgmn@immt.pwr.wroc.pl

Introduction

Poland and other countries aspiring to full membership in the

European Community have to bridge many gaps in a very short time.

The discrepancies between them and the members of the Community

span almost every aspect of life - from the law to pollution of

water, soil and atmosphere. Yet, there is an enormous potential

in these future members of the EU - given a chance their young

generations can join the greater family of the European nations

bringing new ideas, skills and enthusiasm.

Wrocław - the city in which the Center

is localized - is uniquely positioned where Poland, Germany, the

Czech and Slovak Republics meet. Furthermore, it is a great

academic center - 11 higher-education establishments with total

enrolment of 111,000 students (17% of its population). As such

Wrocław is a perfect candidate for a hub of scientific and

technological exchange between the East and the West of Europe.

Establishing of the Center of

Excellence "Sol-Gel Materials and Nanotechnology" in

Wrocław was aimed primarily at creating an international network

of research groups (originating from universities, national labs

and other research-oriented establishments), companies interested

in new technologies and materials as well as local-government

institutions and integrating this network into the greater

European Research Area. That networking would occur in several

intersecting areas by building contacts: between scientists from

different fields (interdisciplinary research), between

scientists and manufacturers (technology transfer) and

between scientists/manufacturers and local communities (response

to local economic and social challenges and needs). The above

mentioned networking between scientific, industrial and

governmental institutions would cover as broad area of Europe as

possible, helping in this way to incorporate the participant

from the NAS into the European Community.

Objectives

The particular objectives envisaged for the "Sol-Gel

Materials and Nanotechnology" Center of Excellence cover:

networking - organizing and coordination of the network

of scientific, industrial and governmental institutions aimed at

enhancing of cooperation between them and yielding joint projects

leading to: obtaining grants, publishing scientific papers,

formulating patents and organizing spin-offs; contacts with other

Centers specializing in related topics will be established and

twinning proposals will be formulated

organization of international and local conferences and

workshops - stimulating exchange of scientific and

technological ideas, bringing together people from different

areas and countries

organizing short-term visits for senior and junior

scientists - helping in establishing contacts aimed at

formulating new research projects capable of obtaining funds from

local sources and the European Commission (e.g. the framework

programs)

publishing a scientific journal - the Center is already

involved in preparing, editing, printing and providing via the

internet of "Materials Science". The journal - which

covers various aspects of new, advanced materials - is a perfect

medium for achieving increase in the scope and impact of the

envisaged network.

Innovative character

New, smart materials and nanotechnology belong to the topics

showing the fastest rate of growth and immense impact on

contemporary science and technology. Due to the advances of

experimental and computational techniques in physics and

chemistry it is possible now to obtain direct information about

molecular and atomic structure of matter (nanometric scale)

and dynamics of physicochemical processes governing its behavior

observed in real-time (femto- and nanosecond scale).

These methods include:

supramolecular chemistry - enabling the

researches to build desired macroscopic structures by controlling

the formation process (chemical recontent/sgmn/actions) on the

nanoscale (e.g. carbon nanotubes (fullerenes),

electroluminescent organic displays etc.)

fast lasers - pulsed lasers operating in nano-

and femtosecond regimes are used to investigate and modify

elementary physicochemical processes enabling researchers to

obtain materials with completely new properties (e.g. quantum

dots, nonlinear optics etc.)

optoelectronics - optical fibers, optical

amplifiers, new generations of detectors are used to integrate,

miniaturize and enhance systems of information collection,

transmission and evaluation yielding more powerful tools for

science and technology

scanning tunneling microscopes (STM) and atomic force

microscopes (AFM) - research tools enabling

visualization of structures of virtually any objects on nanoscale

spectroscopic techniques - such methods as NMR,

UV-VIS-IR absorption techniques, Raman scattering,

luminescence measurements, ESCA etc. yield fast and reliable

information on composition and properties of materials under

investigation.

The above mentioned tools and techniques are just a few of a

fast growing family of techniques enabling researches to

conceive, build, test and apply new advanced materials which

structure and properties are controlled on the molecular and

atomic levels.

The sol-gel technique is one of the fastest growing fields of

contemporary chemistry. The main advantage of this process stems

from the fact that it offers an alternative approach to

conventional production of glasses, glass-like materials and

ceramics of various properties and applications. Conventional

glass preparation requires melting of the precursors at high

temperatures, rapid cooling and subsequent vitrification of the

glassy material. This procedure highly restricts choice of

substances which can be entrapped in the glass products.

Furthermore, the way in which conventional glass is produced

makes thin films preparation extremely cumbersome. Production of

porous glassy materials via the conventional melting is similarly

inconvenient.

The sol-gel technology enables

production of doped glassy materials either as porous dry gels ("xerogels")

or densified materials. Since the process starts from aqueous

solutions of precursors it is possible to immobilize in

glass-like materials various substances even as fragile as

proteins (yielding bio-content/sgmn/active glasses).

Furthermore, contrary to the conventional methods of glass

production it is possible to obtain doped materials with

extremely large dopants concentrations - a crucial feature in

production of, for example, nonlinear optics based on rare-earth

doped glasses and ceramics (e.g. erbium fiber-optical

amplifiers for telecommunication industry). Another

attrcontent/sgmn/active feature of this technology is the fact

that sol-gel materials can be obtained as bulks, thin films (on

various supports) and powders.

Various materials obtainable by the sol-gel technique and the

processes leading to their production are shown in below:

Bulks

Sol-gel technologies

The SGM&N Center of Excellence is

content/sgmn/actively involved in designing, production,

investigations and applications of various materials of the

sol-gel origin. Examples of the main thematic areas:

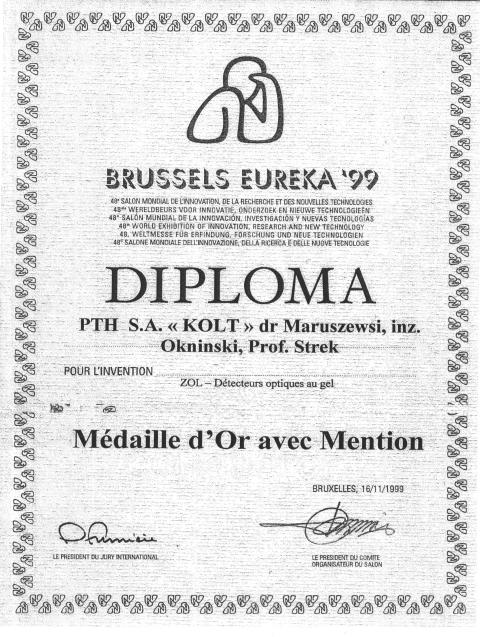

optical sensors (optodes) - the idea is based on

changes of optical parameters of content/sgmn/active (sensing)

molecules physically entrapped in (or, in some cases, covalently

bound to) porous sol-gel thin films (on planar or fiber-optical

supports). Those changes are induced by changing external

physico-chemical parameters such as temperature, hydrostatic

pressure or presence of analyte molecules or, for example,

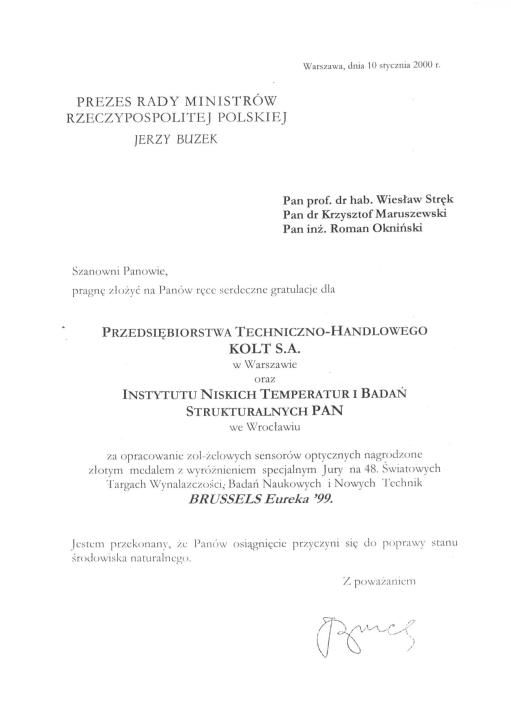

bacteria [e.g. a Gold Medal with Distinction during

the 48th World Exhibition

of Innovation, Research and New Technologies Eureka'99 for

"sol-gel optode of gaseous ammonia"]

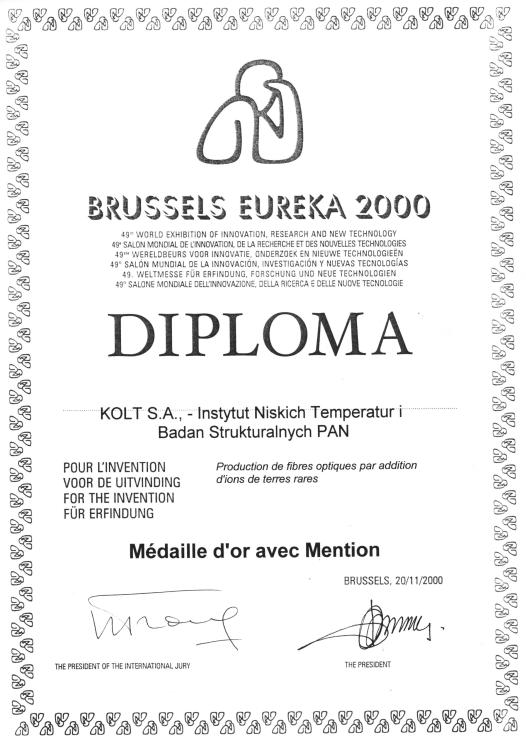

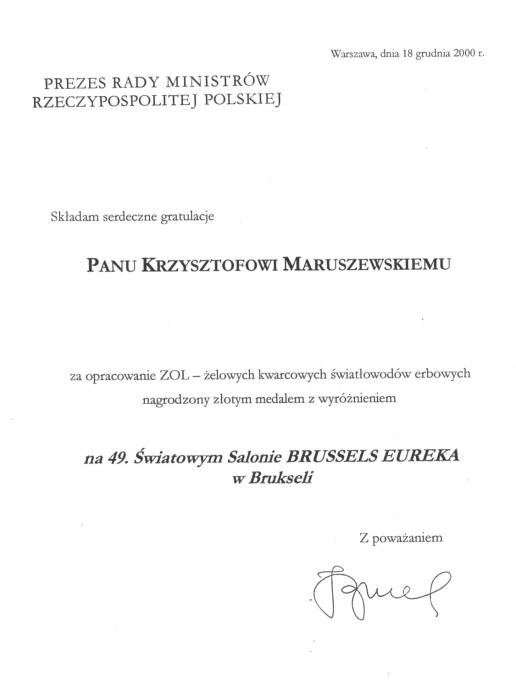

non-linear optoelectronics - the sol-gel

technique is used to obtain densified glasses and ceramics doped

with high concentrations of, for example, rare earth

content/sgmn/active ions [e.g. a Gold Medal with

Distinction during the 49th

World Exhibition of Innovation, Research and New Technologies

Eureka'00 for erbium doped sol-gel preforms for fuber-optical

amplifiers]

nanomaterials - e.g. nanopowders consisting of

uniform spheres of submicron sizes; such spheres can further

modified with various content/sgmn/active substances yielding

materials exhibiting, for example, the photonic effect (e.g.

for optical integrated circuits)or several orders of

magnitude increase in intensity of Raman signal (e.g. for

medical biosensors based on the SERS efect).

The Center of Excellence is coordinated through the Management

Board. The role of the Management Board is to:

· develop long-term plans concerning the Center

strategic research directions,

· obtaining financial support and expand the

Center capabilities

· control the Center financial status

· coordinate contacts with industry and local

governments

· coordinate the staff policy and stimulate the

staff development.

The Board consists of:

- the Scientific Coordinator

- the task leaders

- editor-in-chief of "Materials Science"

The members of the Board have proven scientific

qualifications. Each of them possesses also leadership qualities.

The Center of Excellence Scientific Coordinator is Prof.

Krzysztof Maruszewski.

The working groups with their leaders are dedicated to

carrying specific tasks:

- Scientific projects - organization of work,

coordination and content/sgmn/active participation in

preparation of grant proposals, spin-offs and other

research-oriented content/sgmn/activities. The working

group will be also responsible for obtaining scientific

results, preparation of papers, reports, patents etc. - Leader

1 - Prof. Wiesław Stręk

- Events - work concerned with all aspects of

organization of conferences, workshops and related events

- Leader 2 - Prof. Marek Rybaczuk

- Information - preparation, actualization and

providing of databases and the Center official web page.

Also, preparation of the Center booklets and maintaining

contacts with the Center partners - Leader 3

- Prof. Jerzy Kaleta

- "Materials Science" journal - editing

and publishing of "Materials Science" - person

responsible - Prof. Juliusz Sworakowski Editor-in-Chief

(Institute of Physical and Theoretical Chemistry,

Technical University of Wrocław)

- The Center office - secretarial support of the

Center of Excellence - person responsible – Dr.

Katarzyna Kozłowska, the Center secretary.

The information flow within the Center core is coordinated by the

Center office. The Scientific Coordinator is

responsible for introducing measures decided upon the Management

Board. The Management Board decisions are subject to

the Supervisory Board advises and revisions. The

Management Board meets every month (or more frequently, if

need arises). The Management Board measures and plans are

consulted with the Supervisory Board every three month.

The Center of Excellence is a structural part of the Technical

University of Wrocław. As such, its infrastructure and working

environment is a part of the University macrostructure. Safety

concerns as well as equal opportunity regulations are thus

warranted by the standing rules of the University. As a public

higher-education facility the Technical University of Wrocław

conforms to the Polish Law and international academic

regulations.

Supervisory Board

The supervisory Board guides and advices the Management Board

in its efforts in leading, coordination and expanding of the

SGM&N Center of Excellence.

The Supervisory Board consists of:

1. Prof. M.A. Aegerter, Institut für Neue Materialien - INM,

Germany

2. dr. J. Czyżewski,ABB Corporate Research, Poland

3. Prof. J. Holsa, University of Turku,Finland

4. Prof. A. Kłonkowski, University of Gdańsk, Poland

5. Prof. J. Legendziewicz,Wrocław University, Poland

6. eng. R. Okniński, KOLT S.A. Technical-Commerce Firm,

Poland

7. Prof. M. Opałło, Institute of Physical Chemistry of the

Polish Academy of Sciences, Poland

8. Prof. J. Phalippou, Laboratoire des Verres - UMR 5587,

Universite de Montplier 2, France

9. Prof. R. Reisfeld,The Hebrew University of Jerusalem,

Israel

10. Prof. M. Bettinelli, Universita degli Studi di Verona,

Italy.

Background information on SGM&N Coordinator

Krzysztof Maruszewski (Ph.D. D.Sc.)

He was born 08.08.1964 in Zielona Góra, Poland. He graduated

from the Faculty of Basic Problems of Technology of Wrocław

Technical University in 1988. His M.S. Thesis "Computer

Simulations of Side Directed Mutagenesis and Is Influence on

Proteins content/sgmn/activity and Stability" was

prepared in the Quantum Chemistry Group under a guidance of prof.

dr hab. inż. A. Sokalski and resulted in publication in Int.

J. Quant. Chem. As a student he was a chairmen of

theAssociation of Biotechnology Students (1987-1988) where he

organized the Ist and IInd National

Biotechnology Seminars. He received three Chancellor of Wrocław

Technical University Awards (1985, 1986, 1988) and Minister of

Higher Education Award ("Primus Inter Pares") in 1987.

He begun his doctoral study at Marquette University,

Milwaukee, WI, USA in the group lead by prof. J. Kincaid in 1989

. During his graduate study at Marquette University he completed

five proficiency exams in the first year of the program and

received: Dennis J. O'Brien Fellowship (1990), Rev. J.P. Raynor,

S.J. Fellowship (1991-1992) and "Certificate of

Accomplishment" in 1994. He obtained his Ph.D. degree

in 1992 for Thesis: "Spectroscopy and Physicochemical

Properties of Ruthenium(II) Polypyridine Complexes in Free

Solutions and Entrapped in Zeolites". He continued

research at Marquette University as an Associate Researcher

during his post-doctoral work (1992-1995).

After return to Poland in 1995 he begun to work in the

Institute of Low Temperature and Structure Research (Polish

Academy of Sciences) in Wrocław and in the Chemistry Department

of Opole University. The Scientific Council of the Institute

granted him a D.Sc. degree for "Physicochemical and

Spectroscopic properties of metal complexes and organic molecules

immobilized in zeolites and sol-gel matrices" in June of

1999. He was nominated for an Assistant Professor position

in the Institute of Low Temperature and Structure Research in

March of 2000. In the same year he was also offered a

professor position at the Wrocław University of Technology

which he accepted (ending my work at the Opole University).

In 1997 a Polish Scientific Research Committee (KBN)

grant "Technology and Physicochemical Properties of Optical

Chemi- and Biosensors (Optodes) Based on Sol-Gel Silica

Matrices" (of which he was a Principal Researcher) was

nominated to the "Polish Nobel" series. The

results of the grant were evaluated as "excellent"

and described in several newspapers and TV programs. At the

present moment he is a Principal Researcher of another three KBN

grants concerned with such devices. He also took part in five

other KBN grants. He was a member of a Coordinating Committee of

a SCI-TECH II grant (program Phare) related also to optical

sensors.

He was awarded:

- a Gold Medal with Distinction during the 48th

World Exhibition of Innovation, Research and New

Technologies Eureka'99,

- a Gold Medal with Distinction during the 49th

World Exhibition of Innovation, Research and New

Technologies Eureka'00,

- an Individual Prize of the Polish Minister of Education

in 2000.

He took part in 8 international conferences and 23 conferences

in Poland. He is an author of 44 published publications and two

books. He has six submitted patents. Number of citations: 178

(1989-2001). He is a supervisor of eight PhD students. He was

an organizer of ten conferences including chairmanship of the

"Sol-Gel Materials 2001" International Conference

(Rokosowo, Poland, 2001). He is a member of the Polish Chemical

Society.

International attrcontent/sgmn/action

The SGM&N Center of Excellence possesses significant, well

proven research capabilities in the field of theory,

manufacturing, investigations and applications of a variety of

sol-gel based materials, including nanomaterials.

The major experimental capabilities of

the Center are based, among others, on the following labs:

· several synthetic labs - full synthetic

capabilities (chemical benches, high-temperature furnaces,

dry-boxes etc.)

· chemical analytical labs - various methods

(electrochemical, chromatographic etc)

· microbiological and biochemical labs -

techniques for biological sol-gel sensoric system

· microscopy labs - Transmission Electron

Microscopes, Scanning Electron Microscopes, various optical

techniques

· lasers lab - complete coverage of optical

laser methods (e.g. argon lasers, krypton lasers, an excimer

laser, a dye laser, a YAG:Nd, a Ti:Sapphire laser etc.)

· spectroscopy lab - UV-VIS-IR absorption and

emission techniques (from liquid-helium to high-temperatures),

Raman scattering, excited states lifetime measurements etc.

· crystallography lab - single-crystal and

powder techniques

· material fatigue lab - various materials

fatigue tests

· computational facilities - the Technical

University Computational Center

The Center has established links with many scientists

representing various fields from Europe and other parts of the

world. Examples of the scientific institutions from which

researchers have visited the Center include:

· Prof. M.A. Aegerter, Institut für Neue

Materialien – INM, Germany

· Prof. V. Zolin, Institute of Radioeneering

and Electronics of the Russian Academy of Sciences, Russia

· Prof. J. Phalippou, Laboratoire des Verres -

UMR 5587, Universite de Montplier 2, France

· Prof. N.V. Gaponenko, Belarusian State

University of Informatics and Radioelectronics, Belarus

· Prof. J. Holsa, University of Turku, Finland

· Prof. R. Reisfeld, The Hebrew University of

Jerusalem, Israel

· Prof. R. Acevedo, Ciudad Universitaria,

Santiago, Chile

· Prof. G. De Sa, Cid. Universitaria, Recife,

Brazil

· Prof. T. K. Anh, Inst. Material Sciences,

Hanoi, Vietnam

· Prof. S. Bratccini, Univ. Modena & Reggio

Emilia, Modena, Italy

· Prof. L. C. Klein, Rutgers State University,

USA

· Prof. D. Millers University of Latvia, Riga,

Latvia

· Prof. H. C. Zeng,National University of

Singapore, Singapore

and many others.

The Center has been visited by many students and post-docs,

among others, from: Finland, France, Germany, China, Vietnam,

Belarus and Italy.

The visits, exchanges and other forms of international

cooperation are possible due to the fact that the scientific

staff of the Center of Excellence communicates (in speech and

writing) in English. Furthermore, French, German and Spanish

speakers are among the Center Polish participants. The senior

scientists of the Center of Excellence possess wide experience in

international contacts (degrees obtained at the foreign

universities, memberships of international societies,

participations in conferences in different parts of the World).

Currently, the SGM&N co-operates with the Network of

Centers of Excellence "Interfacial Effects, Novel Properties

and Technologies of Nanostructured Materials" (Acronym

NANOstructured materials) in developing of nanostructured

ceramics for optoelectronics applications.The Center was

represented during the II Workshop of the Network of Centers of

Excellence (5-6 October 2001, Ulm Germany).

Sol-gel technology - Introduction

The sol-gel technology emerged within the last two decades and

quickly became one of the most important and promising new

material fabrication methods. It enables researches to design and

fabricate a wide variety of different materials with unique

chemical and physical properties. The sol-gel materials are based

on silica, alumina, titania and other compuonds. The sol-gel

technology allows to fabricate: monolithic and porous glasses,

fibres, powders, thin films, nanocrystalllites, photonic

crystals. A broad spectrum of different sol-gel derived materials

opens a variety of new applications in a broad range of fields:

optoelectronics (optical sensors, lasers, filters, photonic

crystals), ferroelectronics, luminophores, scintillator ceramics,

cathodoluminescent screens, powder lasers, anti-reflection

coatings, superconductors, telecommunication (optical fibers and

wave guides), medicine (bio-glasses), catalysis, anticorrosion

coatings, new chemicals for agriculture, pharmacy (controlled

drug delivery systems).

The following technology themes are under current development

in the Center of Excellence: fabrication of porous monolithic and

thin film glasses, fabrication of glasses doped with transition

metal and rare eart ions, fabricontent/sgmn/action of optical

sensors (optodes) of various physical and chemical parametres,

fabrication of nanometric crystallites, fabrication of pure and

doped submicron spherical particles, fabrication of

inorganic-organic materials hybrid.

The sol-gel technique

Conventional glass preparation requires melting of the

precursors at high temperatures, rapid cooling and subsequent

vitrification of the glassy material. This procedure highly

restricts choice of substances, which can be entrapped in the

glass products. Basically only metal oxides and some inorganic

salts can survive such drastic conditions avoiding thermal

decomposition. Furthermore, the way in which conventional glass

is produced makes thin films preparation extremely cumbersome and

the only method of preparation of porous classical glasses

requires etching or partial dissolving (e.g. Vycorâ glass). On

the other hand glass and glassy materials possess several useful

features for optical applications such as transparency,

homogeneity, mechanical sturdiness, high refrcontent/sgmn/active

index etc.

An alternative approach to glass and glass-like materials is

offered by the, so called, sol-gel technology. The process itself

is known for more than a century, but it has gained a new

importance in the last two decades after pioneering results of

Dislich. He and other researchers improved the chemistry of the

process so much that it is now possible to obtain samples in days

(or even hours - in case of thin films) rather than months (or

years) like in the case of the early samples.

The sol-gel technique is based on hydrolysis of liquid

precursors and formation of colloidal sols. The precursors are

usually organosilicates (e.g. TEOS - tetraethoxysilane) yielding

silicate sol-gel materials. However, the method is not restricted

to the silicon compounds - for example compounds of zirconium,

vanadium etc. can be used as precursors leading to materials

possessing different physico-chemical properties. Furthermore, it

is possible to obtain modified organosilicate precursors with

direct Si-C bonds (which do not undergo hydrolysis) and

possessing terminal functional groups (e.g. -NH2, -SH2 etc.).

Such precursors, either pure or mixed with the conventional ones,

yield inorganic-organic materials with mechanical (e.g.

elasticity) and physico-chemical properties (e.g. wetability)

modified by the organic components of the inorganic polymer

network. The functional groups can be also used for covalent

binding of various chemicals (including biomolecules) giving

specifically modified glassy materials.

In the case of the most often employed silicate sol-gel

matrices, manufactured from hydrolizates of various

alkoksysilanes, the chemical recontent/sgmn/actions involved in

the gel formation involve the precursor hydrolysis and the

subsequent formation of the silicate network.

At this stage a wet gel is produced which, upon drying, yields

porous xerogels. The drying is accompanied by liquid expulsion

from the pores (syneresis) and substantial matrix shrinkage often

leading to cracks (mainly due to the capillary pressure).

The hydrolysis process is significantly improved (accelerated)

if conducted at pH 7. Thus, addition of acid (typically HCl(aq))

or base (typically NH4OH) speeds up this process.

After the hydrolysis the acidity of the sol is neutralized slowly

to approx. 7 pH, what stimulates the gelation process. At this

stage a mechanically unstable "wet" gel is formed.

Drying of wet gels (even at ambient temperatures) leads to

xerogels ("dry gels"). Xerogels are stable, transparent

and insoluble in water and most of organic solvents and porous

solid materials.

In cases when fully-densified sol-gel glasses are sought,

extensive drying at temperatures close to the vitrification

temperatures will yield such materials (e.g. for silicate glasses

it is necessary to heat at quartz vitrification temperature

Vg&asymp1300°C). This enables obtaining glasses in

situations when it is not feasible via the conventional melting

techniques (e.g. heavily-doped with certain temperature-resistant

materials).

Since the early steps of the sol-gel process occur in liquid

phase, it is possible to add basically any substance (as

solutions or suspensions) at this stage. Simple mixing provides

uniform distribution of the dopant within the liquid host phase.

After the gelation the guest molecules become physically

entrapped within the now solid host matrix. Furthermore, the

hydrolysis, doping and gelation occur usually at ambient

temperatures - allowing entrapment of even such delicate

molecules as proteins without their decomposition. Sol-gel doped

matrices, obtained in the above described manner, are of the form

of xerogels and possess a network of internal pores and cavities

enabling the entrapped molecules to interact with the surrounding

medium. Furthermore, the doped matrices usually possess good

optical characteristics (transparency and high

refrcontent/sgmn/active indexes). Those features are of key

importance for production of optical sensors (optodes).

Submicron silica spheres prepared by the

sol-gel method

Another convenient feature of this technology is the fact that

the sol-gel samples can be obtained as bulks, thin films and

powders. It has to be noted that bulk sol-gel samples suffer very

often from internal cracks, leading to their destruction. This

effect is caused by evaporation of solvent molecules from the

network of pores of the drying gels. The ensuing capillary

pressure is high enough to cause the material collapse. However,

for reasons only partially understood, sol-gel thin films are

virtually immune from this destructive effect. Thus, for example

sol-gel optodes based on such thin films possess all the

attrcontent/sgmn/active features of the sol-gel materials being,

at the same time, virtually free from the most troublesome

drawback of the method i.e. samples cracking.

The sol-gel technique is one of the fastest growing fields of

contemporary chemistry. The main advantage of this process stems

from the fact that it offers an alternative approach to

conventional production of glasses, glass-like materials and

ceramics of various properties and applications. The sol-gel

technology enables production of doped glassy materials either as

porous dry gels ("xerogels") or densified materials.

Since the process starts from aqueous solutions of precursors it

is possible to immobilize in glass-like materials various

substances even as fragile as proteins (yielding

bio-content/sgmn/active glasses). Another attrcontent/sgmn/active

feature of this technology is the fact that sol-gel materials can

be obtained as bulks, thin films (on various supports) and

(nano)powders. Such matrices, content/sgmn/activated by doping,

impregnation or covalent bonding, yield materials which can be

used as, among other possibilities, optical sensors, catalysts,

medical materials (e.g. bone implants), content/sgmn/active (e.g.

"smart windows") and passive coatings (e.g.

scratch-resistant or antireflective) or various optical materials

(e.g. scintillators, powder lasers, amplifiers etc.).

References:

[1] Ebelman, H. (1847). C. R. Acad. Sci., 25, 854.

[2] Dislich, H. (1971). Glastechn. Ber., 44, 1.

[3 Wolfbeis, O.S. (Ed.) (1991). Fiber Optical Sensors and

Biosensors, CRC Press, Boca Raton, Florida.

[4] Maruszewski, K., Strommen, D.P. and Kincaid, J.R. (1993). J.

Am. Chem. Soc , 115, 8345.>br/> [5] Maruszewski K. and

Kincaid J.R. (1995). Inorg.Chem., 34, 2002.

[6] Maruszewski, K., Andrzejewski, D. and Stręk, W. (1997). J.

Luminesc., 72-74, 226.

[7] Maruszewski, K., Jasiorski, M., Salamon, M. and Stręk, W.

(1999). Chem. Phys. Lett., 314, 83.

[8] Lakowicz, J.R. (Ed.) (1994). Topics in Fluorescence

Spectroscopy Vol. 4: Probe Design and Chemical Sensing,Plenum

Press, New York.

[9] Marazuela, M.D., Moreno-Bondi, M.C. and Orellana, G. (1998).

Appl. Spectrosc., 52, 1314.

[10] Campbell, M., Yang, Y., Wallace, P.A. and Holmes-Smith, A.S.

(1997). Opt. Rev., 4, 111.

[11] Nakamoto, K. (1978). Infrared and Raman Spectra of Inorganic

and Coordination Compounds, John Wiley, New York.

[12] Clark, R. J. H. and Hester, R. E. (1978 up to now). Advances

in Infrared and Raman Spectroscopy.

[13] Long, D. A. (1977). Raman Spectroscopy McGraw-Hill, New

York.

[14] Strommen, D. P., (1984). Laboratory Raman Spectroscopy, John

Wiley, New York.

[15] unpublished results.

[16] Stöber, W., Fink, A. and Bohn, E. (1968). J. Colloid

Interface Sci., 26, 62.

[17] Jasiorski, M., Maruszewski, K. and Stręk, W. (2002).

Mat.Sci., 20, 51.

[18] Maruszewski, K., Jasiorski, M., Hreniak, D., Stręk, W.,

Hermanowicz, K. and Heiman, K. J. Sol-Gel Sci.Techn., in press.

[19] Campion, A. and Kambhampati, P. (1998). Chem. Soc. Rev., 27,

241.

[20] Li, X.Y., Petrov, V.I., Chen D. and Yu, N.T. (2001). J.

Raman Spectr., 32, 503.

[21] Kurokava, Y., Imai, Y. and Tamai, Y. (1997). Analyst, 122,

941.

[22] Litorja, M., Haynes, C.L., Haes, A.J., Jensen T.R. and Van

Duyne, R.P. (2001). J. Phys. Chem. B, 105, 6907

Optical fiber sensors and luminescence

biosensors

prepared by the sol-gel method

The idea behind the sol-gel optical sensors (optodes) is based

on changes of optical parameters of content/sgmn/active (sensing)

molecules physically entrapped in (or, in some cases, covalently

bound to) porous sol-gel thin films. Those changes are induced by

changing external physico-chemical parameters such as

temperature, hydrostatic pressure or presence of analyte

molecules or, for example, bacteria. There are several kinds of

optical signals which could be used as analytical response of

such optodes. In general, one can observe changes of:

- time of decay of the sensing molecules luminescence,

- intensity of light absorbed or emitted by the sensing

molecules

- changes in vibrational spectra (bands intensity and

frequency) of the sensing molecules,

- polarization properties of the sensing molecules.

Electronic spectroscopy in the visible region offers several

advantages stemming from the fact that relatively small number of

inorganic, organic or metalloorganic molecules possesses

electronic transitions in the VIS range (color). This fact lowers

the possibility of optical interference with the sensing

molecules coming from unwanted molecules (in most cases organic),

which might diffuse into the matrix pores or adhere to the optode

surface. Furthermore, spectral bands corresponding to such

transitions are usually broad in condensed phases (liquids and

solids) and, often, even in gases. This property makes them

easier to detect. Simple colorimetric measurements of acidity

supply an example of this analytical method. In this case changes

in pH result in changes of absorption patterns (color) of organic

indicator dyes such as, for example, phenolophtaleine,

bromocresol, rosolic acid etc.

As it has been mentioned, optodes can be based on detection of

changes of polarization properties of the sensing molecules bound

to sol-gel matrices. For example, it is possible to covalently

bind large, biological molecules labeled with luminophors to the

surface of a sol-gel thin film in such a way that the

macromolecule retains partial rotational freedom. If some other

molecule recognizes and binds to the labeled biomolecule its

rotation can be hampered what leads to changes of the luminophore

emission polarization anisotropy. The system based on the this

effect can be employed as a luminescent sensor for detection of

certain bacteria.

The luminescence biosensor based on

detection of changes of depolarization of luminescence

Thin films of titania and silica-titania

composites

New methods of fabrication of the thin films obtained by the

sol-gel method for bacteriostatic and optical applications have

been developed. Both types of materials are prepared from

hydrolyzed alkoxides of silicon and titanium (or their mixtures).

The well-known antiseptic properties of silver are due to

influence of silver ions on various microorganisms. Silver ions

are produced by oxidation of metallic Ag in the air. It is

related to the fact that this process yields a thin layer of AgO

on the metallic core of particle. Thus, it is important to

prepare materials with well dispersed silver particles,

possessing high specific surface and nanometric metal

precipitates. These requirements are met by the sol-gel derived

materials. Easy preparation of thin films and the simple process

of silver doping allows to prepare antiseptic and non-toxic for

humans materials for medical applications and the food industry.

Emission spectra (a) and luminescence

decays (b) recorded for TiO2 doped with

Eu3+ and co-doped with Eu3+

and silver particles

Besides antiseptic properties of silver doped materials, a

strong influence of metallic, nanostructured Ag on the

luminescence efficiency of light emitting lanthanides ions, which

are generally used as luminophores, has been found recently. This

effect is due to phonon-plasmon intercontent/sgmn/action which is

present in dielectric materials doped with nanosized metallic

particles under optical excitation. The luminescent thin films of

nanocrystalline TiO2 content/sgmn/activated with

Eu-ions (red luminophore) and co-doped with silver particles have

been successfully obtained by the sol-gel method and their

emission properties have been investigated (Fig.1). The effect of

silver doping on the luminescence lifetimes increasing, which

indicates on the increase of emission efficiency from Eu3+-ions,

has been found. The fabricated material can be used as a new,

planar luminophores for optoelectronic applications (for instance

in Field Emission Displays (FEDs)).

Magnetic Powders

Understanding the correlation between magnetic properties and

(nano)structure involves collaborative efforts of chemists,

physicists and materials scientists to study both fundamental

properties and potential applications. Magnetic nanoparticles of

a single magnetic domain size possess very interesting properties

and the potential to replace many of the conventional magnetic

materials.

Ferromagnetic materials, magnetic powders, have been widely

used as magnets, cores and wave absorbers.

Nanoparticles of magnetic materials are used in magnetic

disks, recording tapes, etc.

Superparamagnetic nanoparticles also find important medical

applications e.g. magnetic cell sorting, magnetocytolysis,

drug-targeting experiments etc.

The correlation between nanostructure and magnetic

properties suggests the classification of nanostructures

morphologies:

Type A

Materials include the ideal ultrafine particle system, with

interparticle spacing large enough to approximate the particles

as nonintercontent/sgmn/acting. The isolated particles with

nanoscale diameters.

Subgroup of Type A

Materials in which magnetic particles are

surrounded by a surfactant preventing intercontent/sgmn/actions.

Ferrofluids, in which long surfactant molecules provide

separation of particles.

Type B

Materials include ultrafine particles with a core-shell

morphology. In type-B particles, the presence of the shell can

help to prevent the particle-particle intercontent/sgmn/actions.

Type C

Nanocomposites are composed of small magnetic particles

embedded in chemically dissimilar matrix. The matrix may or may

not be magnetocontent/sgmn/active.

Type D

Materials consists of small crystallites dispersed in

noncrystalline matrix. The nanostructure may be two-phase, in

which nanocrystalites are a distinct phase form the matrix, or

the ideal case in which both the crystallites and matrix are made

of the same material.

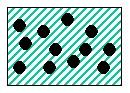

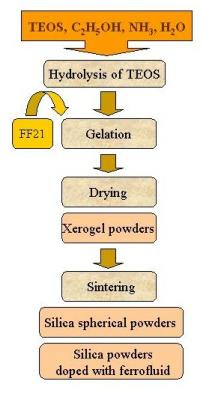

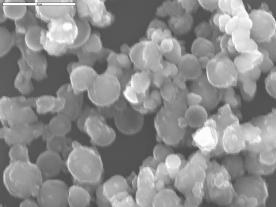

The spherical powders doped with ferrofluid and other magnetic

compounds are prepared by sol-gel process, modified in the part

of TEOS hydrolysis technique. Spherical hydrous silica particles

with narrow size distribution were previously produced by

Stöber, et al. via the hydrolysis/condensation method. Under

conditions of constant stirring at room temperature, TEOS

(tetraethylorthosilicate) was added to a solution of

reagent-grade ethanol and concentrated ammonium hydroxide

solution. The TEOS underwent hydrolysis/condensation

recontent/sgmn/action, forming (poly)silicic acid. Within

minutes, precipitation of uniform spherical particles occurred.

Figure 1. Diagram of the sol-gel preparation procedure for SiO2

powders doped with the magnetic fluid (FF21)

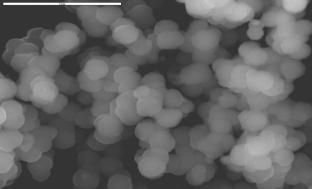

Figure 2. SEM photographs of spherical magnetic powders.

Organic - inorganic polymer hybrid

An organic-inorganic hybrid

polymer hybrid materials has been obtained by combining organic

termo- and photopolymerization and the sol-gel process. The

organic and inorganic phases are formed from two interpenetrating

polymeric networks. The family of organic–inorganic hybrid

materials have attracted considerable attention due to their

interesting properties such as: molecular homogeneity,

transparency, flexibility and durability. Such hybrids are

promising materials for various applications, e.g.: solid state

lasers (optical components), replacements for silicon dioxide as

insulating materials in the microelectronic industry,

anti-corrosion and scratch resistant coatings, contact lenses or

host materials for chemical sensors, membrane materials and many

medical and dental applications, such as: dental filling

materials. Other areas of applications are catalysis,

chromatography. The potential applications and technologies are

limited due to their unique properties and characteristics. An organic-inorganic hybrid

polymer hybrid materials has been obtained by combining organic

termo- and photopolymerization and the sol-gel process. The

organic and inorganic phases are formed from two interpenetrating

polymeric networks. The family of organic–inorganic hybrid

materials have attracted considerable attention due to their

interesting properties such as: molecular homogeneity,

transparency, flexibility and durability. Such hybrids are

promising materials for various applications, e.g.: solid state

lasers (optical components), replacements for silicon dioxide as

insulating materials in the microelectronic industry,

anti-corrosion and scratch resistant coatings, contact lenses or

host materials for chemical sensors, membrane materials and many

medical and dental applications, such as: dental filling

materials. Other areas of applications are catalysis,

chromatography. The potential applications and technologies are

limited due to their unique properties and characteristics.

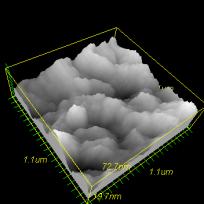

Figure 2. AFM micrograph of SiO2/acrylamide-HEMA copolymer

hybrid.

Organic-inorganic hybrid materials are synthesized by the

sol-gel process. The sol–gel process is an interesting approach

to preparation of the inorganic phases in the organic–inorganic

hybrid materials due to the fact that it can occur in liquid

solutions at room temperature. The sol–gel technology provides

an excellent way of obtaining transparent and mechanically stable

films, bulk glasses and powders. Furthermore, it provides a

convenient way of producing porous materials. The general sol-gel

recontent/sgmn/action is based on hydrolysis of various alkoxides

to form respective silanols. This is followed by a condensation

recontent/sgmn/action occurring between silanols or silanols and

alkoxides. The sol-gel process involves evolution of inorganic

networks through the formation of a colloidal suspension (sol)

and gelation of the sol to form a network in a continuous liquid

phase (gel). The precursors for syntheses are used alkoxysilanes

such as tetraethoxysilane (TEOS) or alkoxytitanium such as

titanium tetrabutoxide (TBT). However, alkoxide such as silica

and titanate are also commonly used in the sol-gel process to

form mixed-presursor inorganic matrices. We are functionalized

surface inorganic materials by vinyl, phenyl, methyl, ethyl and

epoxy group.

The organic precursor such as

acrylamide or 2-hydroxyethylmethacrylate (HEMA) or mixture of

these monomers were introduced to the liquid hydrolyzed silicate

solutions. The compositions silica/organic monomers were

irradiated by UV light at room temperature. The organic polymer

and copolymer phase have been prepared by radical polymerization

with benzil used as a photo-radical initiator. The organic

polymer also are prepared via thermopolymerization. The obtained

materials have been investigated by spectroscopic (IR, Raman),

microscopic (SEM, AFM) and thermal analysis (TGA, DTA)

techniques. The N2-adsorption were used to

characterize the textural properties such as: specific surface

areas (SBET), pore volumes (Vp), average

pore sizes (Rp) and micropore volumes (VDR).

The complete adsorption-desorption isotherms and pore size

distributions were analyzed following the Dollimore-Heal method.

The textural parameters was measured for organic-silica hybrid

materials and for materials after pyrolysis. The pyrolysis of the

inorganic-organic polymer hybrid samples was performed at 600°C

under oxygen flow. The textural parameters was measured for

organic-silica hybrid materials and for materials after

pyrolysis. The pyrolysis of the inorganic-organic polymer hybrid

samples was performed at 600°C under oxygen flow. All

organic-inorganic polymer hybrid samples are non-porous

materials. However after complete pyrolysis at 600oC

all samples show high microporosity .The result of the

pyrolysis silica show that pyrolysis of the sample leads to

mezoporous material. Contact angle vs. water (Langmuir balance),

hardness (Vicer's method), roughness (AFM) were also measured.

Organic phase is composed of organic hydrophobic and amphyphilic

acrylate homo- and copolymers.  However, we have obtained

hydrophilic organic-inorganic interpenetrating However, we have obtained

hydrophilic organic-inorganic interpenetrating

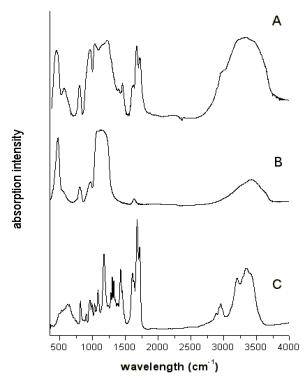

polymer network. Figure 3 presents FT-IR spectrum of the SiO2/acrylamide-HEMA

copolymer hybrid, sol-gel SiO2 bulk and free organic

copolymer. The spectra show that is possibility to obtain

organic-inorganic polymer hybrid by the sol-gel method and the

organic photo-polymerization method. The picture of the hybrid

bulk sample (Figure 1) shows that the samples are transparent and

do not exhibit irregularities which might indicate such phase

separation.

At present, we have investigated structure and properties of

hybrid SiO2-TiO2-organic polymer xerogels

obtained by the sol-gel method. We have the intention to describe

the preparation, the chemical structure and the mechanical

properties of the organic-inorganic silica-titanium polymer

hybrid. Further our research area will be synthesis and

properties of titanium-based organic-inorganic polymer hybrid

xerogels.

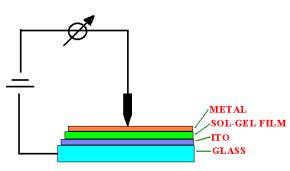

We have developed organic–inorganic polymer hybrid for

photo- and electroluminescence, which we can used as organic

light emitting diode (OLED). These materials we have obtained by

the sol-gel method. The basic of classic organic light-emitting

diode is a Metal (e.g.: indium tin oxide) – Electroconductive

polymer (e.g.: polypyrole) – Electroluminescent material

(e.g.: organic rare earth compounds) - Metal (e.g.: aluminium

or calcium). In our work electroconductive polymer and

electroluminescent material have been interpenetrated in

inorganic sol-gel materials. Porous inorganic sol-gel film have

been good hole layer – injecting and transporting layer. OLED

have attrcontent/sgmn/active properties such as high

luminescence, low driving voltage, easy fabrication of large

areas and a wide range of emission colors.

Sol-gel materials under gamma rays

Gamma rays which are generated by radiocontent/sgmn/active

materials, have the smallest wavelengths of any other wave in the

electromagnetic spectrum. They are very penetrating and can

kill living cells. Therefore, they are used in medicine to kill

cancerous cells or in food industry to sterilization. Gray is the

SI unit of absorbed dose of radiation. The gray is the absorbed

dose when the energy per unit mass imparted to matter by ionizing

radiation is one joule per kilogram (1 Gy = 1 J/kg).

In our research, influence of gamma rays on organic molecules

entrapped in sol-gel matrices is investigated. Tetraethoxy- and

tetramethoxysilan (TEOS and TMOS) are used to obtain the

matrices. The compounds enclosed in porous silicate bulks are

dyes with strong absorption band in the visible region (metal

phthalocyanines, complexes of ruthenium(II) or safranine). Dyes

are dissolved in water or organic solvent and added to the sol.

The obtained matrix shows very good transmission properties in

the investigated region even after irradiation. The translucent

bulks are exposed to 60Co radiation source at room

temperature, at a dose rate of 15,8 Gy/min. For comparison, the

solutions of the dyes are also irradiated.

When the dye dissolved in solvent is exposed to gamma

radiation, the decay of absorbance is observed. The rate of the

decay depends among others on a kind of solvent, exposure time,

concentration of the dye and the level of oxygen. When, for

example, magnesium(II) phthalocyanine (MgPc) dissolved in

dimethyl formamide (DMF) is exposed to irradiation, gamma rays

cause the complex decomposition. This effect is registered as the

discoloration of the solution and the decay of the absorption.

The complex has three absorption bands in the visible region

(~ 604, 642 and 670 nm). The fast decrease in the absorbance is

observed for all of them (Fig.1). The initial blue color almost

disappears at doses of about 1 kGy (for the initial

concentration of the dye 0,62 mM). The decay of absorbance at

670 nm versus dose or gamma irradiation is exponential.

Neodymium bisphthalocyanine (NdPc2) in DMF has two

absorption bands in the visible region (~ 630 and 670 nm) which

can be assigned to the monomeric and dimeric form of the

phthalocyanine. The fall in absorption depends on the solvent.

For the complex in DMF, at the beginning of irradiation, the

longer-wavelength band increases and the other decreases its

intensity. The monomer : dimer ratio changes during

irradiation. Probably the dimer form degradation is faster. In

DMF : H2O solution the ratio is constant at the

beginning. The faster decrease in the dimer form seems to appear

in the later stage of radiation. In one case the decay of

absorbance versus dose or gamma irradiation is exponential, in

the other case, it is linear.

Gamma rays also changes the properties of silicate matrix. It

becomes nontransparent in the blue region of electromagnetic

spectrum at big doses. The absorption shifts from 270 to

400&minus450 nm for 1000 kGy. The bulks, from transparent

and colorless, becomes yellowish. The changes are quite similar

for bulks from TEOS and TMOS.

The absorption

spectra of phthalocyanines in silicate matrix are different as

compared to the solutions. For MgPc, there is a broad band with

maxima at 610, 680 and 750 nm. The decay of absorption intensity

under gamma rays is much slower in the xerogel (Fig.2). It slows

a lot especially in the later stage of irradiation. Even up to

radiation dose of 1100 kGy, the bulk samples are still color and

the sol-gel matrix has very good transmission properties in

the investigated region. Further research

were difficult because the bulk started to disintegrate. The absorption

spectra of phthalocyanines in silicate matrix are different as

compared to the solutions. For MgPc, there is a broad band with

maxima at 610, 680 and 750 nm. The decay of absorption intensity

under gamma rays is much slower in the xerogel (Fig.2). It slows

a lot especially in the later stage of irradiation. Even up to

radiation dose of 1100 kGy, the bulk samples are still color and

the sol-gel matrix has very good transmission properties in

the investigated region. Further research

were difficult because the bulk started to disintegrate.

For NdPc2 in the sol-gel matrix the broad

absorption band consists of at least three overlapping bands.

They also can be assigned to the monomeric and aggregated forms

of the Pc. First doses of radiation causes fast degradation.

After abut 40 kGy the degradation is much slower. The blue

shift, broaden and increase of the band intensity is observed.

The longer-wavelength band is assigned to monomer. It is possible

that faster degradation of this form causes apparent shift and

the absorption increase. The change in the monomer&harrdimer

equilibrium is also possible. The variation in the absorbance

depends on the concentration of the dopant. For different

concentrations, the shift and absorbance growth appear at the

beginning or in the later stage of irradiation.

To apply the sol-gel matrix with organic compounds as a

gamma radiation sensor, it should show proper dependence of

absorbance on gamma dose. Only in some cases the dependence is

linear or, more often, exponential. Such relationship can be

found only for some range of doses. Usually, the straight line

can be drawn for small doses and the curve line for larger doses.

Perhaps some molecules could be applicable to the dosimeters

purpose. For instance, safranine which shows linear decay in a

large range from 0 to 40 kGy (Fig.3) or

tris(1,10-phenantroline)ruthenium(II) with exponential

decay from 0 to 150 kGy.

As a result of intercontent/sgmn/action between matter and

ionising radiation, radicals

and solvated electrons are formed. They can later react

with molecules in the environment. The radiation induced

transformation of complex compounds are:

– redox processes leading to the change of

oxidizing degree of central ion which changes the coordination

number and causes the molecule decomposition;

– radicals effect (recontent/sgmn/actions with

radicals);

– recontent/sgmn/actions with excited molecules of

solvents.

But the final products of the decomposition of many molecules

are unknown. The radicals formed under high-energy radiation can

be responsible for the degradation. The macrocyclic rings are

especially sensitive

to radicals attack. The cleavage of carbon&minuscarbon,

carbon&minushydrogen and carbon&minusnitrogen bonds is

possible in the dyes molecules.

The decrease in the dye decomposition

rate in the sol-gel matrix might be related to lower

concentration of free radicals formed in it upon gamma radiation.

Another possibility is that the matrixinduced change of the

macrocycle complex surroundings occurs which might increase the

dye stability.

The main conclusions of the research are:

– gamma rays cause decomposition of organic

molecules entrapped in sol-gel matrix.

–

– the dye decomposition rate is lower in the

sol-gel matrix in comparison with dyes in solutions.

– the linear or exponential decay in absorbance

occurs only in a particular range of doses.

– in the xerogel less radicals can be formed or

the matrix increases the dye stability.

Silica, titania and silica-titania powders

Silica (SiO2), titania (TiO2) and

silica-titania (SiO2-TiO2) powders have

been prepared by sol-gel method using silicate precursors:

tetraethoxysilane (TEOS), phenyltriethoxysilane (TPhOS),

vinyltriethoxysilane (TVOS), (3-Aminopropyl)-triethoxysilane

(APTES) and titanium precursors: titanium(IV) ethoxide (TEOT),

titanium(IV) buthoxide (TBOT) and titanium(IV) isopropoxide

(TIPO). Silicate and titanium precursors were dissolved in

ethanol, butanol and isopropanol. The recontent/sgmn/actions were

catalyzed by ammonia. Various SiO2, TiO2

and SiO2-TiO2 powders can be produced

depending on the solvent/precursor ratio and the solvent used

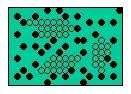

during the hydrolysis. Morphologies of the obtained powders were

characterized by the Scanning Electron Microscopy (SEM) and

Transmission Electron Microscopy (TEM). The sol-gel process has

been used as a synthetic route to obtain silica and titania

particles with spherical morphology. The results are presented

in Figures 1-4.

A A

B B

C C

D D

E E

F F

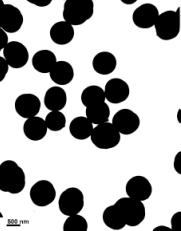

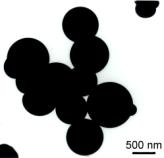

Fig. 1. TEM micrograph of silica powders prepared from TEOS

(A-E) and APTES (F).

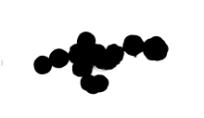

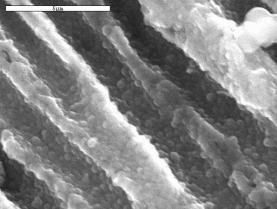

A A  B B

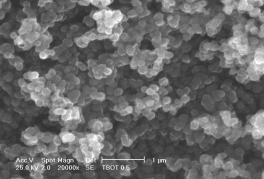

Fig. 2. SEM micrographs of titania powders

prepared from TBOT (A,B)

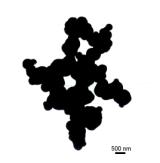

A A  B B

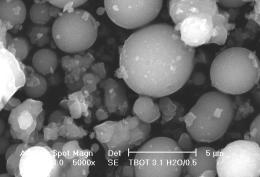

Fig. 3. SEM and TEM micrographs of titania

powders prepared from TIPO (A,B).

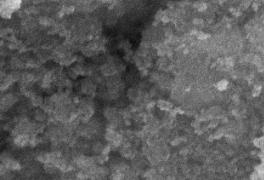

A A  B B

Fig. 4. SEM micrographs of silica-titania

powders: TPhOS/TEOT (A) and TVOS/TEOT (B).

Some of the obtained titania powders possessed spherical

grains. The grains size and shape depends on the synthetic

conditions and the precursors used. The smallest grain sizes were

observed for the recontent/sgmn/actions with TIPO and the biggest

for the TBOT syntheses. The important parameter controlling the

particle formation and aggregation was the water/precursor molar

ratio.

TG-DTA and X-ray powder analysis

Titanium dioxide TiO2 has three naturally occuring

crystalline structures: anatase, brookite and rutile. The rutile

form is thermodynamically most stable at standard conditions. The

metastable anatase and brookite forms can be transformed to

rutile by heating. The sol-gel synthesized titanium powders are

amorphous in nature and the crystalline structure is achieved

only after heat treatment. The temperature needed for the

crystallization is dependent on the recontent/sgmn/action

conditions and the preparation route. The exothermic peak around

4000C (Fig. 5) is related to the phase-transformation

to rutile. The X-ray diffractogram of the titania powders shows

the diffrcontent/sgmn/action pattern characteristic to rutile

crystalline phase (Fig. 6). No peaks characteristic to anatase

and brookite appear in powders heated at 5000C.

Fig. 5. TG-DTA curves of titania powdres

prepared by TEOT.

Fig.6. XRD patterns of titania powders prepared

from TEOT and calcinated at 5000C.

Molecular imprinting

Molecular imprints are obtained by introduction of inorganic,

organic or biological molecules during the polymerization step.

Subsequent removal of the molecules leaves stable vacant imprints

and designed sites for the recognition of the template molecules.

Materials obtained in this way are ideally suited for

applications such as separations, chemical sensing and catalysis.

Surfaces of silica particles were molecularly imprinted with

organic molecules: safranin, rodamine B, rosolic acid. Silica

particles were prepared in the presence of ethanol solution of

these molecules. Organic molecules were removed by calcination.

The resulting imprinted particles show adsorption of organic

molecules. The molecular adsorption of the surface-imprinted

particles was larger than in the case of particles without

imprints.

content/sgmn/activity progress report of the year 2003

The Center is effectively expanded and broaden its scope.

· First of all, the Center web page has been established

(http://sgmn.immt.pwr.wroc.pl/). It contains information about

the Center profile, its content/sgmn/activities, the coordinating

Institutions (the Wrocław Technical University and the Institute

of Low Temperature and Structure Research, Polish Academy of

Sciences), the management, link to "Materials Science"

etc.

· The Center has applied and been accepted to the International

Sol-Gel Society (www.isgs.org) and is listed at and linked to

the largest international portal dedicated to the sol-gel

science: The Sol-Gel Gateway (www.solgel.com/Research/resgr.htm).

· The Center has presented its content/sgmn/activities at the

largest Polish Fair – the International Poznań Fair, Poznań,

Poland (mtp.mtp.pl). Our presentation took form of a stand

(#66/Pavilion 14) dedicated to the Center and presented during

the forum: Science for the Economy (a part of the 75th

Fair of Industrial Technologies and Investment Goods) on

9-12.06.2003. There were, among other materials presented,

available for the Fair participants: posters, booklets and CD

discs pertaining to the Center content/sgmn/activities.

· The scientists participating in the Center have

content/sgmn/actively took part in basic and applied research in

the field of sol-gel materials and nanoscience. One of the major

achievements is the Gold Medal at the 52nd

World Exhibition of Innovation, Research and New Technologies

"Eureka" in Brussels (November 2003) received for

"Nanocomposite Materials for content/sgmn/active

Textiles". The submicron silica spheres doped with

nanoclusters of metallic silver has been used for

content/sgmn/activation of textile coatings giving them

antibacterial capability.

· The scientists affiliated with the Center has published a

total of 16 scientific papers in 2003.

The Center has expanded its contacts with other groups working

in the field. These contacts will lead to enhancement of the

Center experimental capabilities, create new opportunities for

fruitful personnel exchanges and lay ground for joint grant

proposals directed to the 6th Framework Program of the

EC. Already, three proposals were submitted to the 6th

Framework Program in 2003. During 2003 scientists affiliated with

the Center submitted several proposals to the Polish Ministry of

Science and Informatization. Two of them have been successful.

The financing of the grants for development of intelligent

textiles based on various doped nanopowders obtained by the

sol-gel method and for the sol-gel–based optical sensors

(optodes) has started with beginning of 2004.

A seminar entitled "The

"Sol-Gel Materials and Nanotechnology" Center of

Excellence - an Overview" was presented, among others:

during the 2nd International Conference "Sol-Gel

Materials", Rokosowo, Poland, June 2003, during the XII

Organosilica Compounds Seminar, Dymaczewo, Poland, October 2003,

at the Vilnius University, Vilnius, Lithuania, November 2003 and

the Institute of Radio Engineering and Electronics of the Czech

Academy of Sciences, Praque, the Czech Republic, December 2003.

The Center content/sgmn/activities were also presented in

several press articles and TV programs. Also, a series of

lectures on new developments in nanotechnology was organized for

high school teachers of physics.

The international journal "Materials

Science" after several-years long break restarted its

operation with the first issue of the completely changed volume

20 at the beginning of 2002. "Materials Science" is

published by the Wrocław University of Technology, in

collaboration with the Institute of Low Temperatures and

Structure Research of the Polish Academy of Sciences and the

Wrocław University of Economics. The journal is accessible in

two ways: the conventional printed form and in the electronic

form. Thus, full texts are available instantly after manuscripts

acceptance (and before the paper version printing) at

www.MaterialsScience.pwr.wroc.pl. This ensures short waiting

times and quick information delivery to scientists worldwide.

During 2003 the journal expanded its operation and scope and the

electronic database has been improved. The high quality of the

scientific papers published and the journal regularity resulted

in "Materials Science" being added to the ThompsonO

ISI Journal Data Base (the "Philadelphia list" at

www.isinet.com/journals) in the autumn of 2003.

SGM2004 is an interdisciplinary meeting

aimed as a platform for information exchange between

prcontent/sgmn/actically and theoretically oriented scientists

interested in materials obtained by the sol-gel technique. The

Second International Conference on Sol-Gel Materials

"Research, Technology, Applications" SGM'03 took place

on 15 - 20 June 2003 in Szklarska Poręba, Poland

(http://smartsite.immt.pwr.wroc.pl/index/SolGel). This second in

a row event gathered around 100 participants from various

countries (Belarus, the Czech Republic, England, Finland,

France, Germany, Israel, Italy, Japan, Lithuania, Poland and

Spain) - doubling its size since the First SGM Conference in

Rokosowo, Poland organized in 2001

(http://www.immt.pwr.wroc.pl/sgm2001). The Conference has covered

a vide field of topics related to various aspects of theory and

prcontent/sgmn/actice of the sol-gel technology.

Some of SGM&N Awards

The SGM&N Team:

Prof. Krzysztof Maruszewski

Prof. Wiesław Stręk

Dr. Marek Jasiorski

Dr. Katarzyna Kozłowska

mgr inż. Dariusz Hreniak

mgr inż. Agnieszka Hreniak

mgr Róża Kornak

mgr Iwona Zaręba-Grodz

mgr inż. Anna Łukowiak

mgr Beata Borak

|